|

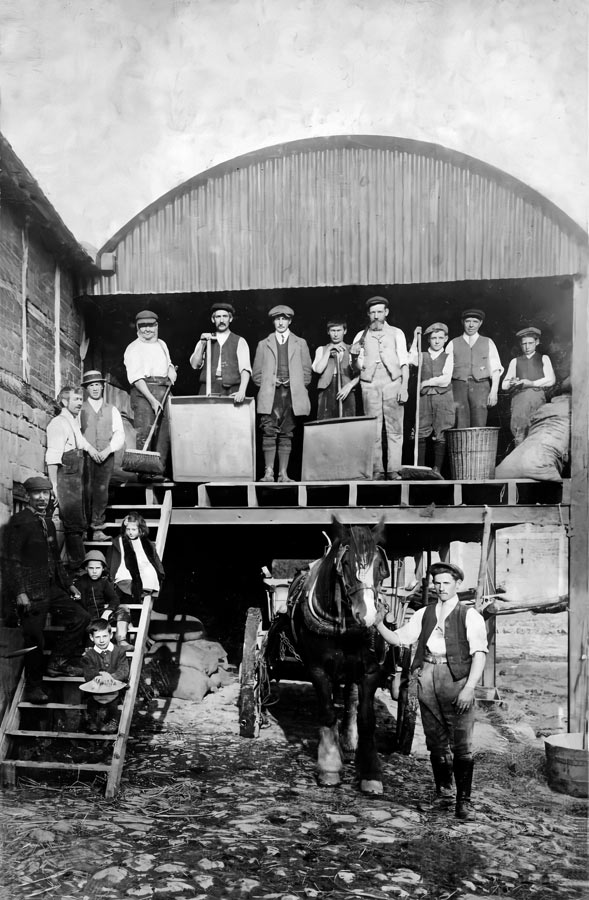

Kiln workers at Ankerdine Farm, pre 1918 (Many thanks to Peter Walker for this photo).Information on the Hop Kilns at Ankerdine Farm

Ankerdine

The hop kilns are square in plan, a shape that became popular again in the 1870s after a long popularity of circular oasts. As the present kilns were not marked on the 1885 Ordnance Survey, they are clearly late 19th Century or very early 20th century. The building envelope survives in an near complete condition, but with altered and inserted fenestration. It is constructed of red, unfrogged brick (the brick size is 210x105x75mm) and has 9" walls. At ground floor level there are three (originally external) arched openings at kiln floor level. Both kilns now have enlarged sliding door openings on the northern elevation, which replaced either doors or windows, the narrow arched heads of which survive. A large mechanical fan system was in use in the kilns from 1911 to 1970, the machinery being made by Samuel C Davidson, Sirocco Works, Belfast. It was originally belt driven from a portable steam engine, but later electric driven. No evidence of this or the earlier heating system now survives. The drying floor has been removed from both kilns but its former position is marked by the former joist pockets. The present flooring within the chambers is a later 20th century insertion. The drying chamber was lined with match boarding nailed to the rafter soffits above. The walls do not appear to have been matchboard lined. The construction is plain and functional without any architectural embellishments. The roof is slate, and the rotating cowls remain. Within the western kiln there is a surviving rotating vane linked tothe rotating cowl above. Whilst the present vane is of clear plastic sheet the cross bar to which it is attached may be an earlier feature. The vane appears to rotate in the breeze propagated by the cowl and serves to cool and exchange the air in the chamber. The arrangement is unusual and may relate to either hop drying or the later use of the kiln as hop-pickers accommodation. The latter use is evidenced by the presence of a sofa and storage lockers. The western kiln appears to have been constructed slightly earlier than the eastern kiln. The evidence for this is a discontinuous vertical joint in the brickwork between the two kilns on both the north and southern faces at the dividing wall. The western kiln was provided with doors at three levels into the earlier kiln range (now the western part of the southern range). The ground floor doorway is accompanied by steps down into the kiln heating chamber. Access for the added eastern kiln heating chamber was via a doorway in the dividing wall from the western kiln at ground floor level, but there were no other links between the kilns at a higher level. It would appear that the drying chamber for this kiln was accessed from the east, where there is a large modern opening (now blocked) at the level of the present floor. The access between the kilns therefore appears rather awkward, and it must be suspected that there was some form of external walkway linking the kilns along the valley between the roof of the northern range and the square kilns. The renewal of the roof structure would have removed most evidence of this, and the area is no longer accessible. Presently the upper part of the eastern kiln is only accessible through a hole crudely knocked through the dividing wall..

.

©peh